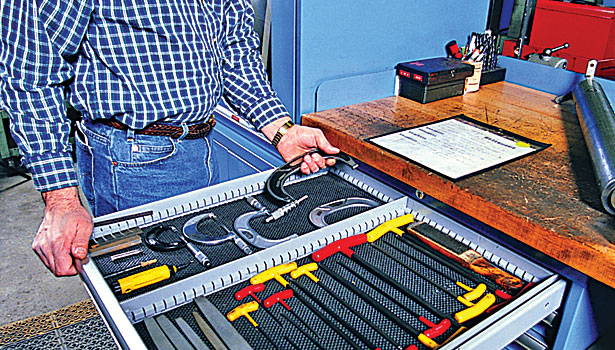

One of the most common examples of 5S in the home is the ubiquitous plastic tray in the silverware drawer (shown earlier).

In fact, you and your team likely use many of the concepts in your home life, so it should not be a big stretch to apply the same logical principles of 5S in your factory or Lean office. In truth, though, whatever version is used, you will likely find an underlying current of common sense in it. simplify) may even describe different steps and have alternate meanings in different companies. Some of the most common terms include: sort, simplify, systematic arrangement, set in order, spic and span, scrub, sweep, shine, standardize, stabilize, sustain, and self-discipline. It is the continuation of the expression started in ‘Straighten’ above: “…, and everything in its place.”īecause translation is an inexact science, you might see many different versions of 5S. Shitsuke (Sustain): This is the industrial discipline that keeps 5S in place.Seiketsu (Standardize): This step entails making and ‘locking in’ the locations designated with ‘straighten.’.Seiso (Scrub): This step entails not only doing an initial cleaning but also making it easy to keep the area clean.Seiton (Straighten): This step entails arranging the work in a manner that makes jobs easier to do.

Seiri (Sort): This step entails getting rid of clutter and unused items.The original 5S terms come from Japanese words: In a nutshell, it entails creating an organized, effective workspace that supports the processes being performed in the area.

One of the fundamental tools in any Lean toolkit is 5S.

0 kommentar(er)

0 kommentar(er)